Rare earth elements (REE), a group of 17 metallic elements, are in nearly every piece of technology, including cellphones, televisions, computers and almost every part of a vehicle. The demand for these elements increases annually, however the supply is limited geopolitically and is mined with environmentally unsustainable practices.

Young-Shin Jun, a professor of energy, environmental and chemical engineering at the McKelvey School of Engineering at Washington University in St. Louis, and her team have created a proof-of-concept solution: extracting REEs from coal fly ash, a fine, powdery waste product from the combustion of coal.

“We wanted to use a greener process to extract REEs than traditionally more harmful processes,” Jun said. “Since the coal has already been used, this process is ultimately a pathway toward reduction and remediation of waste products.”

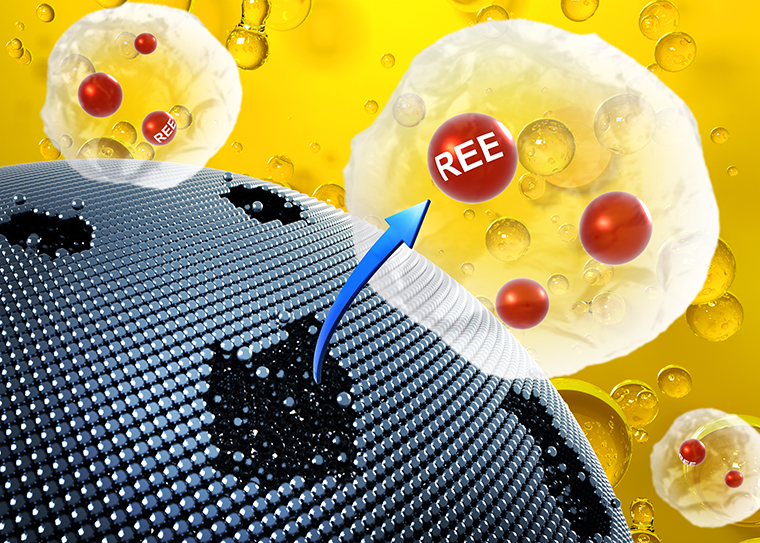

Jun and her former doctoral student, Yaguang Zhu, now a postdoctoral scholar at Princeton University, developed this novel extraction process using supercritical fluid, commonly used to decaffeinate coffee, to recover these critically needed REEs from material that would have otherwise been discarded in a landfill. With more than 79 million metric tons of coal fly ash generated in the U.S. annually, Jun’s team reported that the potential value of the REEs that could be extracted from coal fly ash in the U.S. is estimated at more than $4 billion annually.

Their work, which appears in the March 2023 issue of RSC Sustainability, is first to show that common and accessible supercritical fluids, including carbon dioxide, nitrogen and air, were able to extract REEs and separate impurities very efficiently.

Read more on the McKelvey School of Engineering website.