The recent spike in food prices isn’t just bad news for your grocery bill. It also impacts the sugars used in biomanufacturing, and it has pushed researchers at Washington University in St. Louis to explore alternative feedstocks.

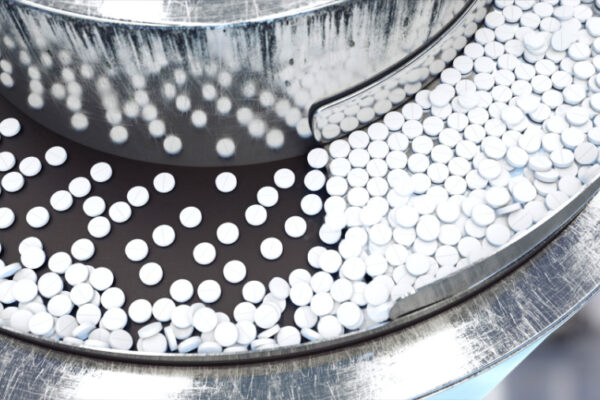

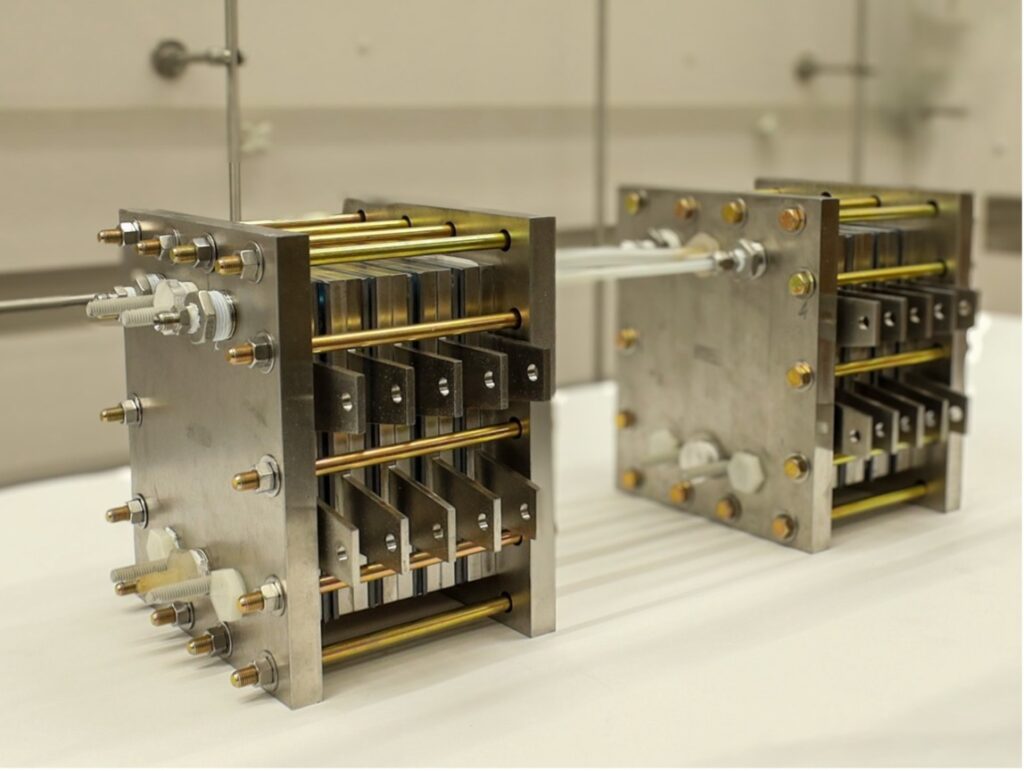

Feng Jiao, the Elvera & William R. Stuckenberg Professor in the McKelvey School of Engineering at Washington University in St. Louis, developed a two-step process to convert carbon dioxide (CO2) into valuable carbon-based materials used in the production of food, plastics and other commodity chemicals. Jiao’s tandem CO2 electrolysis produces acetate and ethylene. Acetate is a close relative of the more familiar acetic acid, or vinegar, which can be used as food for microbes used in biomanufacturing, and ethylene is a common component found in plastics and other polymers.

In a study published June 3 in Nature Chemical Engineering, Jiao demonstrated that his tandem CO2 electrolyzer, which was specifically engineered for enhanced production of multi-carbon products, successfully scales up to produce a kilogram of chemicals per day at high concentration and purity. This represents a 1,000% increase in scale over previous demonstrations, offering a pathway to industrial feasibility, which Jiao and his team further supported with a techno-economic analysis showing the technique’s commercial viability.

A key achievement of Jiao’s system is not only enhanced production capability, but also the system’s resilience against industrial impurities, a critical factor in real-world applications. This resilience ensures that the system can maintain its high performance amid challenges posed by typical industrial environments.

“This is the first step in scaling up to commercial applications,” Jiao said.

Read more on the McKelvey School of Engineering website.