Turning waste carbon into useful products is a vital part of sustainable manufacturing. Recycling carbon dioxide creates carbon monoxide, which through electricity can be converted into energy-rich compounds. However, existing devices for this process use anion exchange membranes that break down over time when exposed to organic materials, making them less effective.

A team of researchers, led by Feng Jiao, the Lauren and Lee Fixel Distinguished Professor in the McKelvey School of Engineering at Washington University in St. Louis, has found that inexpensive and robust materials, porous separators called diaphragms, can be viable alternatives to these membranes in the carbon monoxide conversion process.

After testing various diaphragms, they found that some of them performed as well or better than polymer-based commercial membranes in various operating conditions.

Their findings were published Sept. 26, in Nature Communications. Wanyu Deng, a postdoctoral researcher, and Siyang Xing, a doctoral student, are first authors on the paper.

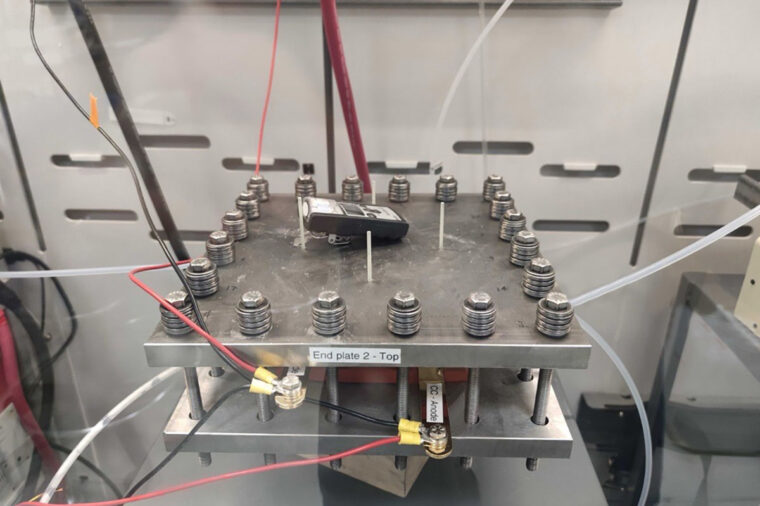

Diaphragms effectively prevent crossover of cathode and anode gas products and are made of low-cost materials. Jiao’s lab created a diaphragm-based carbon monoxide electrolyzer design. After testing a variety of materials, the electrolyzer cells using Zirfon (a type of diaphragm product containing zirconium dioxide) maintained efficiency for more than 250 hours at 60 degrees Celsius, while the best commercial membranes only lasted within 150 hours. Additionally, a scaled-up Zirfon-based electrolyzer operated steadily for 700 hours.

“These results show that diaphragms can be a scalable and durable solution for carbon monoxide conversion, making the process cheaper and more compatible with renewable energy sources,” said Jiao, who also is a professor in the School of Public Health, is director of the Center for Carbon Management and associate director of the National Science Foundation CURB Engineering Research Center.

The team will continue to refine their electrolysis technologies for greater efficiency, as the more affordable and efficient the waste-gas conversion process becomes, the faster manufacturing systems can become circular and sustainable.

Deng W, Xing S, Maia GWP, Wang Z, Crandall BS, Jiao F. Diaphragm-based carbon monoxide electrolyzers for multicarbon production under alkaline conditions. Nature Communications, Sept. 26. https://doi.org/10.1038/s41467-025-63004-1

This research was supported by the Gates Foundation (INV-051757) and the National Science Foundation (EEC-2330245).