The process of biomanufacturing requires engineering microbes to produce useful chemicals and materials from carbon-neutral processes. But current biomanufacturing cannot get beyond small-production scale unless it can outcompete big oil.

The petrochemical industry produces chemicals and material building blocks at a low cost because these processes can run nonstop. However, performing microbial biomanufacturing continuously faces numerous challenges and presents a significant hurdle for economically viable bioproduction.

At the McKelvey School of Engineering at Washington University in St. Louis, researchers are working on giving biomanufacturers a competitive edge by solving the challenge of setting up continuous fermentation.

Fuzhong Zhang, the Francis F. Ahmann Professor of energy, environmental and chemical engineering, will lead an interdisciplinary team to develop a genetic “switch” to make microbes work at high efficiency over extended periods during bioproduction.

The team, which includes biological engineers from WashU (Professors Marcus Foston, Yinjie Tang and Joshua Yuan), the University of California, Riverside, and Texas A&M University, has received up to $5.2 million from the Defense Advanced Research Projects Agency via the Switch program to tackle problems in continuous fermentation.

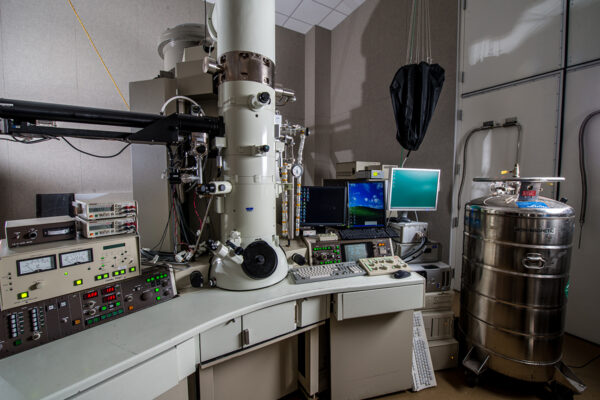

Biomanufacturing works much like beer brewing — the oldest form of biomanufacturing. Along with breweries, the supplement industry makes use of these processes to produce chemicals such as omega-3 fatty acids available at the pharmacy. Those industries grow microbes, such as microalgae, fungi or bacteria, in bioreactors (large enclosed tanks) to produce the chemical in batches, just as we use the byproducts of yeast to make beer.

This batch system is used throughout different industries to make products, but it’s much less efficient than continuous fermentation, where microbes are fed and allowed to operate for weeks or even months at a time.

But continuous fermentation often leads to mutation or even an inexplicable worker strike, where the microbes stop making the sought-after chemical despite the same conditions.

Zhang’s team will work to develop a switchable system to keep the microbes on task.

“Microbes were evolved to duplicate themselves, not to make any product for us,” said Zhang, who also is the co-director of McKelvey Engineering’s Synthetic Biology Manufacturing of Advanced Materials Research Center. “Once we force them to make a product, we’re working against evolution.”

Many fermentation factors can make biomanufacturing unstable. After addressing one unstable factor, another workaround often pops up elsewhere, like a game of whack-a-mole.

Instead of chasing all the chaotic reactions of the microbes, Zhang and colleagues will develop tools to make evolution work for them.

“The switch system will address problems in long-term continuous fermentation, making biomanufacturing more efficient and cheaper, to the benefit of everyone,” Zhang said.