Growing algae in wastewater has been a hot topic in research for years. News reports for decades have touted the latest research as bringing us within reach of new sources of fertilizer or environmentally friendlier biofuel.

So far, however, these promises have not been fulfilled. One reason is that the algae grown in wastewater tends to be contaminated. But even if it wasn’t, it’s not clear that the applications for the algae that have been dreamed up in the lab would be the most realistic applications outside the lab.

Inside one lab, however, at the McKelvey School of Engineering at Washington University in St. Louis, researchers had applications in mind when they developed a new method to use nutrients recovered from wastewater to grow algae that is more than twice as pure as algae grown directly in conventional wastewater.

The research was published online late last year in the journal Water Research.

Zhen (Jason) He, professor of energy, environmental and chemical engineering, said the problem starts with the quality of algae we currently get from wastewater.

“Gas prices may seem expensive, but it’s still relatively inexpensive in the United States,” He said. Pricewise, biofuels from algae grown in wastewater simply can’t compete.

One of the reasons growing algae this way is so expensive is quality control.

Algae can grow in wastewater because of the nutrients found therein; one person’s waste is another algae’s food. Nitrogen, phosphorus, dissolved organic carbon — these byproducts of our waste are the nutrients algae need to grow.

Unsurprisingly, however, when you are trying to grow algae in wastewater, “what you get is messy,” He said. “It’s wastewater. Yes, you get algae. You get bacteria also. Anything will grow there. So, algae biomass grown in wastewater has low value, which reduces the overall economic profit.”

Turning the process on its head

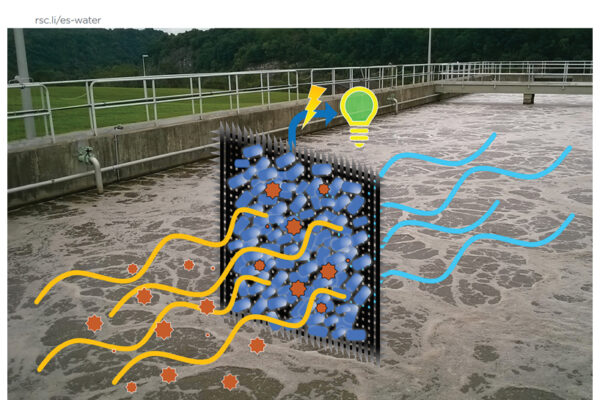

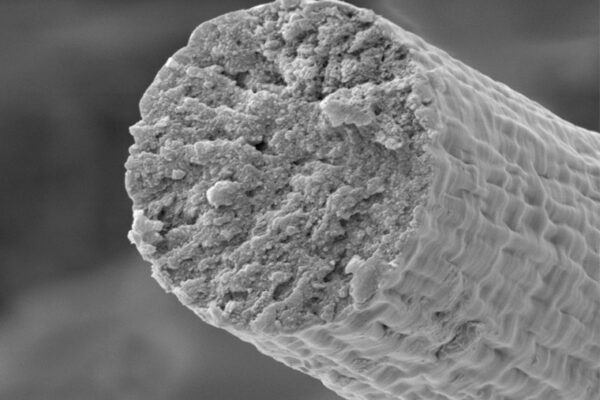

He and his team developed a way to turn the process on its head, bringing the nutrients from the wastewater to the algae, rather than putting algae into the wastewater. The process hinges on a microbial electrochemical system developed in He’s lab.

Using this system, He and his team were able to use bioelectricity to extract nutrients and then take them to the algae, feeding them more efficiently and leading to purer algal biomass.

To test its purity, He’s team took wastewater from Washington University’s food services; in half of the sample, they added algae. In the other half, they used He’s wastewater treatment system to extract the nutrients from the wastewater, which they then used to feed algae.

Then they measured the purity of the resulting algal biomass.

The resulting biomass from algae fed on extracted nutrients was more than 90% algae. When the algae were grown in the wastewater, the resulting biomass was just 32% algae. “It was almost 70% bacteria,” He said.

Being able to produce such pure algae opens the door for applications that He already knows are in demand. For instance, certain algae can synthesize secondary chemicals, some of which are used in dietary supplements — such as antioxidants — or certain pigments, or even bioactive compounds used in pharmaceuticals. Fuzhong Zhang, also a professor of energy, environmental and chemical engineering, who was a part of the research team, specializes in genetically engineering microorganisms that produce certain compounds.

Ultimately, these algae could be used to synthesize certain compounds in a biorefinery — like an oil refinery where petroleum (crude oil) is transformed into gasoline and other useful products — but without the same environmentally hazardous repercussions.

First, however, He is set on increasing the purity of the algal biomass he can produce. “I want 95% or 98% algae,” he said. Then he will go on to investigate what conditions are most conducive to particular algae to determine what might be the most economically viable compound to produce.

Importantly, any technology developed will be applicable not just to Washington University wastewater, but to municipal wastewater nearly anywhere in the world.

“Municipal wastewater is similar everywhere,” He said. “Wastewater in Europe is the same as wastewater in Los Angeles. And you want to develop something where people in other places can say, ‘That can work here.’”

This work was financially supported by a faculty startup fund of Washington University in St. Louis. The authors thank Metropolitan St. Louis Sewer District for providing the sludge inocula, Washington University Dining Service for providing the food wastewater, and Dr. Christopher Oxford (Washington University in St. Louis) for his assistance with cation analysis.

The McKelvey School of Engineering at Washington University in St. Louis promotes independent inquiry and education with an emphasis on scientific excellence, innovation and collaboration without boundaries. McKelvey Engineering has top-ranked research and graduate programs across departments, particularly in biomedical engineering, environmental engineering and computing, and has one of the most selective undergraduate programs in the country. With 140 full-time faculty, 1,387 undergraduate students, 1,448 graduate students and 21,000 living alumni, we are working to solve some of society’s greatest challenges; to prepare students to become leaders and innovate throughout their careers; and to be a catalyst of economic development for the St. Louis region and beyond.