As our electronic devices get more sophisticated, they also generate more heat that must be released for maximum performance. Damena Agonafer, a mechanical engineer and materials scientist in the McKelvey School of Engineering at Washington University in St. Louis, is perfecting a way to dissipate the heat through a unique process involving tiny liquid drops on top of an array of micropillars.

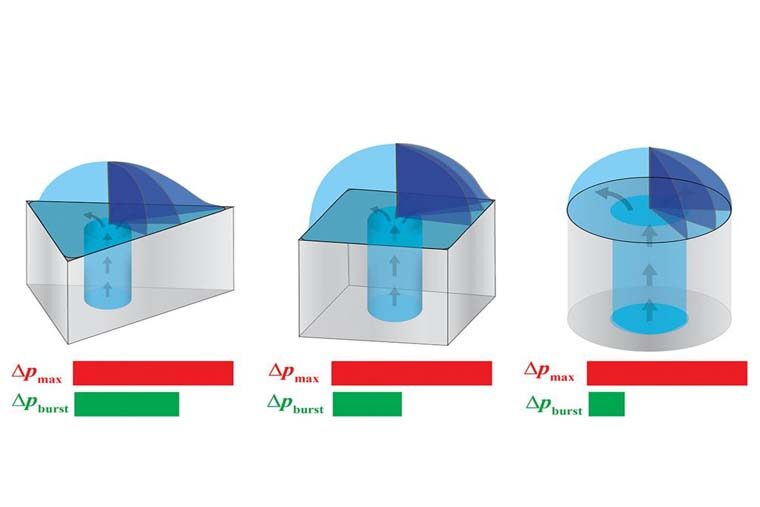

In new research published on the cover of the journal Langmuir Sept. 17, Agonafer, assistant professor of mechanical engineering & materials science, worked with droplets of different liquids on micropillar structures of different shapes: triangles, squares and circles. The drops on the tops of the micropillars are similar to when a glass of water is overfilled just enough to make a hemispheric shape, or a meniscus, on the top of the glass before one more drop causes it to spill over.

In new research published on the cover of the journal Langmuir Sept. 17, Agonafer, assistant professor of mechanical engineering & materials science, worked with droplets of different liquids on micropillar structures of different shapes: triangles, squares and circles. The drops on the tops of the micropillars are similar to when a glass of water is overfilled just enough to make a hemispheric shape, or a meniscus, on the top of the glass before one more drop causes it to spill over.

Agonafer’s micropillar structures hold droplets of liquid with their sharp edges that form an energy barrier on the surface that keeps the liquid from spilling over. Some liquids, such as water, create high surface tension and create maximum pressure when the contact line is pinned on the edge of the inner pore of the micropillar. Other liquids, such as isopropyl alcohol or refrigerant, create low surface tension and create maximum pressure when the contact line is pinned on the outer edge of the structure.

Agonafer found that the shape of the micropillar made a difference in the amount of liquid it held before the droplets spilled over. The work, the first to study liquid retention on asymmetric pillar structures, provides insight into design of surface micro- and nanoengineered structures in science and engineering.

“We want the droplet to stay in place on top of the micropillar because it aids with the cooling process,” Agonafer said. “The asymmetric shape enhances the heat transfer. The meniscus is where the highest evaporative heat transfer occurs, so we wanted to try to increase that region.”

Previously, Agonafer developed a membrane with circular microscopic pillars designed to dissipate the heat in electronic devices. He based the membrane on the water-repellent skin of the springtail, an ancient insect that can breathe through its skin even under water. It was the first work to use low-surface-tension liquid within porous membrane structures.

In the new research, Agonafer and his team found that a droplet pinned on a triangular micropillar took the least amount of liquid before it spilled over, known as critical burst volume. When they used the high surface-tension liquids isopropyl alcohol and dielectric liquid, changing the shape of the micropillar from circular to triangular led to an 83% and 76% reduction in critical burst volume, respectively.

Ultimately, he found that the circular micropillar had a more uniform buildup of liquid volume than the triangular and square micropillars.

“The retention of liquids on the asymmetric pillar structures had very different characteristics than the cylindrical pillar,” he said. “The liquid meniscus may not necessarily wet the entire top of the surface of the asymmetrical micropillar, creating a significant challenge for analyzing the equilibrium profile.”

Agonafer and his lab are now working to optimize the shape and the pattern of the micropillars on an array toward developing an evaporative heat exchange device.