In a world overrun by petroleum-based plastics, scientists are searching for alternatives that are more sustainable, more biodegradable and far less toxic to the environment.

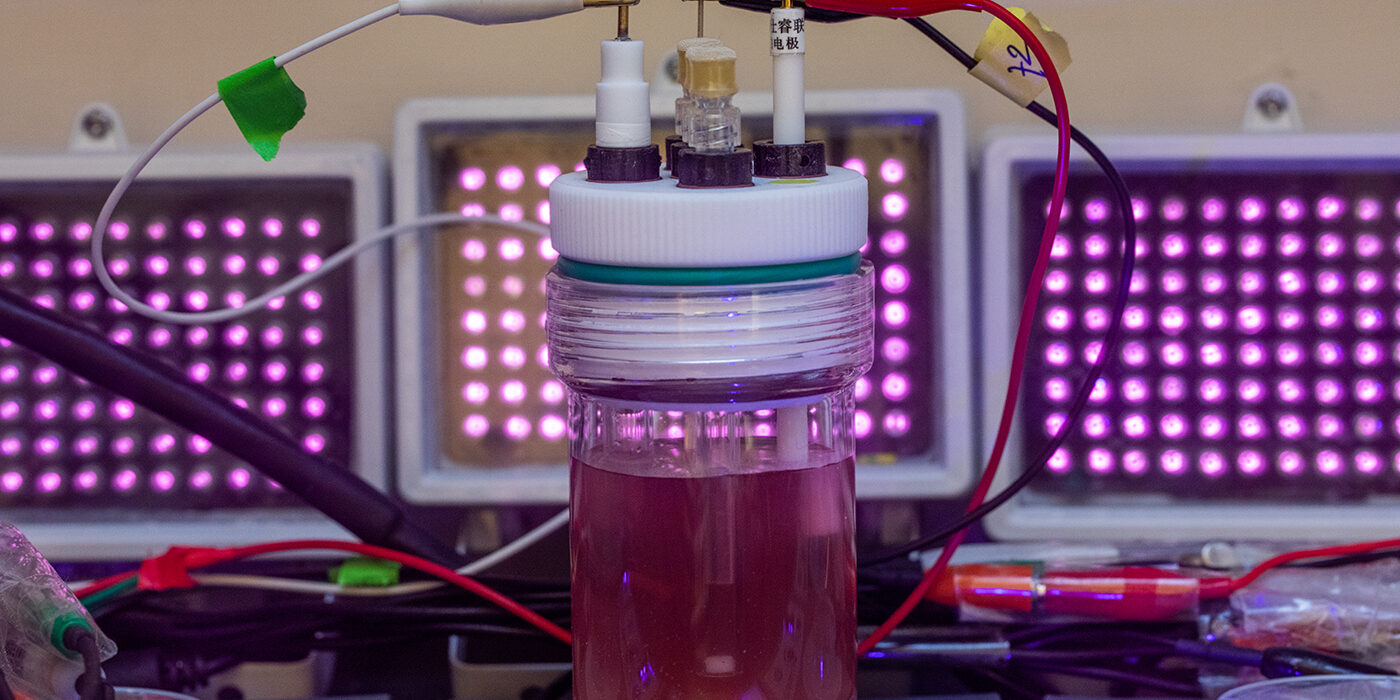

Two new studies by biologists at Washington University in St. Louis highlight one potential source of game-changing materials: purple bacteria that, with a little encouragement, can act like microscopic factories for bioplastics.

A study led by graduate student Eric Conners found that two relatively obscure species of purple bacteria have the ability to produce polyhydroxyalkanoates (PHAs), natural polymers that can be purified to make plastic.

Another study led by research lab supervisor Tahina Ranaivoarisoa showed that genetic engineering could coax a well-studied but notoriously stubborn species of purple bacteria to dramatically ramp up its production of PHAs.

Conners and Ranaivoarisoa work in the lab of Arpita Bose, an associate professor of biology in Arts & Sciences and corresponding author of the new studies. “There’s a huge global demand for bioplastics,” Bose said. “They can be produced without adding CO2 to the atmosphere and are completely biodegradable. These two studies show the importance of taking multiple approaches to finding new ways to produce this valuable material.”

Purple bacteria are a special group of aquatic microbes renowned for their adaptability and ability to create useful compounds from simple ingredients. Like green plants and some other bacteria, they can turn carbon dioxide into food using energy from the sun. But instead of green chlorophyll, they use other pigments to capture sunlight.

The bacteria naturally produce PHAs and other building blocks of bioplastics to store extra carbon. Under the right conditions, they can keep producing those polymers indefinitely.

As the WashU biologists report this week in Microbial Biotechnology, two little-known species of purple bacteria in the genus Rhodomicrobium showed a remarkable willingness to produce polymers, especially when energized with small amounts of electricity and nourished with nitrogen. “It’s worth taking a look at bacteria that we haven’t looked at before,” Conners said. “We haven’t come close to realizing their potential.”

Rhodomicrobium bacteria have unusual properties that make them intriguing contenders as natural bioplastic factories. “It’s a unique bacteria that looks very different from other purple bacteria,” Conners said. While some species float around cultures as individual cells, this particular genus forms interconnected networks that seem especially well-equipped to produce PHA.

Other types of bacteria can also produce bioplastic polymers with some help. As reported in Applied and Environmental Microbiology, the WashU researchers used genetic engineering to coax impressive levels of PHAs out of Rhodopseudomonas palustris TIE-1, a well-studied species typically reluctant to produce the polymers. “TIE-1 is a great organism to study, but it’s historically not been the best for producing PHA,” Ranaivoarisoa said.

Several genetic tweaks helped boost the output of PHA, but one approach was especially successful. Researchers saw impressive results when they inserted a gene that increased the natural enzyme RuBisCO, the catalyst that helps plants and bacteria capture carbon from air and water. With the help of the super-charged enzyme, the usually sluggish bacteria turned into relative PHA powerhouses. The researchers are optimistic a similar approach could be possible with other bacteria that might be able to produce even higher levels of bioplastics.

In the near future, Bose plans to take a closer look at the quality and possible uses of the polymers produced in her lab. “We hope these bioplastics will produce real solutions down the road.”

Originally published on The Ampersand website