Medicines such as insulin for diabetes and clotting factors for hemophilia are hard to synthesize in the lab. Such drugs are based on therapeutic proteins, so scientists have engineered bacteria into tiny protein-making factories. But even with the help of bacteria or other cells, the process of producing proteins for medical or commercial applications is laborious and costly.

Now, researchers at Washington University School of Medicine in St. Louis have discovered a way to supercharge protein production up to a thousandfold. The findings, published Dec. 18 in Nature Communications, could help increase production and drive down costs of making certain protein-based drugs, vaccines and diagnostics, as well as proteins used in the food, agriculture, biomaterials, bioenergy and chemical industries.

“The process of producing proteins for medical or commercial applications can be complex, expensive and time-consuming,” said Sergej Djuranovic, associate professor of cell biology and physiology and the study’s senior author. “If you can make each bacterium produce 10 times as much protein, you only need one-tenth the volume of bacteria to get the job done, which would cut costs tremendously. This technique works with all kinds of proteins because it’s a basic feature of the universal protein-synthesizing machinery.”

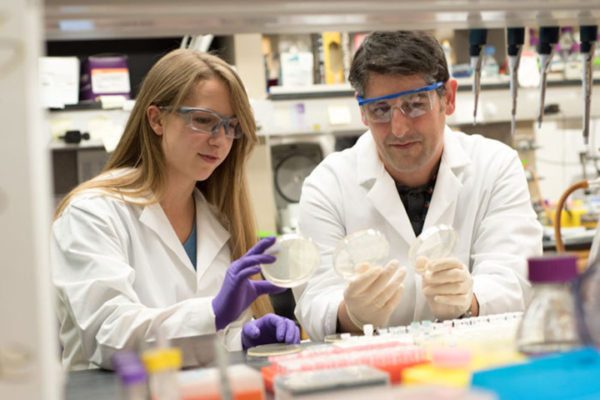

Proteins are built from chains of amino acids hundreds of links long. Djuranovic and first author Manasvi Verma, an undergraduate researcher in Djuranovic’s lab, stumbled on the importance of the first few amino acids when an experiment for a different study failed to work as expected. The researchers were looking for ways to control the amount of protein produced from a specific gene.

“We changed the sequence of the first few amino acids, and we thought it would have no effect on protein expression, but instead, it increased protein expression by 300%,” Djuranovic said. “So then we started digging in to why that happened.”

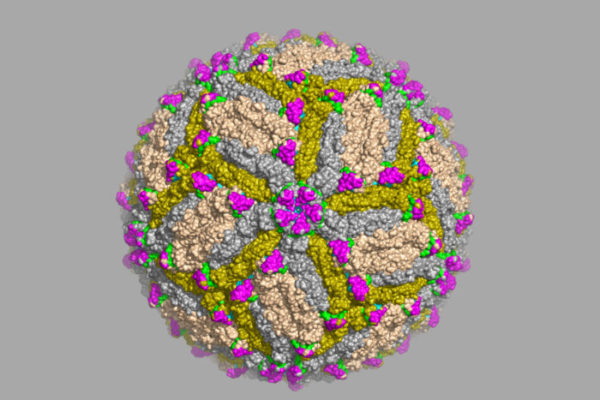

The researchers turned to green fluorescent protein, a tool used in biomedical research to estimate the amount of protein in a sample by measuring the amount of fluorescent light produced. Djuranovic and colleagues randomly changed the sequence of the first few amino acids in green fluorescent protein, generating 9,261 distinct versions, identical except for the very beginning.

The brilliance of the different versions of green fluorescent protein varied a thousandfold from the dimmest to the brightest, the researchers found, indicating a thousandfold difference in the amount of protein produced. With careful analysis and further experiments, Djuranovic, Verma and their collaborators from Washington University and Stanford University identified certain combinations of amino acids at the third, fourth and fifth positions in the protein chain that gave rise to sky-high amounts of protein.

Moreover, the same amino-acid triplets not only ramped up production of green fluorescent protein, which originally comes from jellyfish, but also production of proteins from distantly related species like coral and humans.

The findings could help increase production of proteins not only for medical applications, but in food, agriculture, chemical and other industries.

“There are so many ways we could benefit from ramping up protein production,” Djuranovic said. “In the biomedical space, there are many proteins used in drugs, vaccines, diagnostics and biomaterials for medical devices that might become less expensive if we could improve production. And that’s not to mention proteins produced for use in the food industry – there’s one called chymosin that is very important in cheese-making, for example – the chemical industry, bioenergy, scientific research and others. Optimizing protein production could have a broad range of commercial benefits.”