Design is critical, but you have to begin with capacity. What is a thing capable of doing?

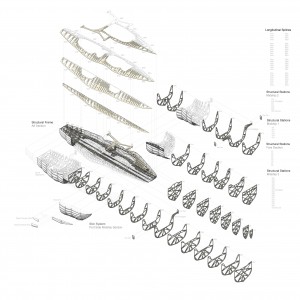

Earlier this month, a group of 10 architecture students from the Sam Fox School of Design & Visual Arts at Washington University in St. Louis unveiled a prototype watercraft in the school’s Steinberg Gallery. With its curved ribs, undulating hull and pleated skin tapering to the nose, the model is elegant and even beautiful — a blue whale ready to brace the waves.

It also represents a unique material investigation. Could expanding polyurethane spray foam — a commercial product typically used for home insulation — be adapted to nautical applications?

“The first half of the project was about learning what the material can do,” said Benjamin Newberry, a master’s candidate in the Graduate School of Architecture and Urban Design. “What are its capacities? How do you convert it into something that floats?”

Using foam samples donated by Fenton-based manufacturer Convenience Projects, the students worked in pairs to design and construct a half-dozen small prototypes, which they tested in the Grand Basin in Forest Park. Two of those prototypes were then integrated and refined to create the final design, which students constructed in the Sam Fox School’s Digital Fabrication Lab.

“When you build something substantial, something at full scale, you begin to appreciate the relationship between the design process and the act of making,” said Jaymon Diaz, senior lecturer and digital fabrication coordinator, who conceived the boat project for his Digital and Analog Fabrication seminar.

“Inevitably you run into issues,” Diaz said. “Things go wrong, things don’t turn out as planned. But that’s one of the major benefits to a course like this.

“Troubleshooting, fixing mistakes — these are really important parts of teaching and learning.”